Concrete Inspection and NDT

Construction professionals need a reliable NDT solution for the evaluation of concrete structures. Geotech’s proprietary ground penetrating radar (GPR) systems can be used for effective concrete inspection and NDT to locate rebar, conduits, and PT cables in concrete slabs, identify voids in concrete, assess the concrete condition, and determine the thickness of concrete slabs. Concrete inspection and NDT is important for the assessment of both new and old structures. For new structures, the main applications are the assessment of the quality of materials. Testing of existing structures is generally related to evaluating their structural integrity. Non-destructive testing can also be used as an initial step for subsequent more invasive and destructive testing.

Concrete Inspection Information

1.) Locate Rebar

Construction and concrete professionals use GPR (ground penetrating radar) for the reliable location of structural reinforcement (rebar) inside concrete slabs before drilling, coring, or cutting. Reinforcement bars can be easily located in real time with Geotech’s Construction Scan series ground penetrating radar solutions, with only single-sided access needed.

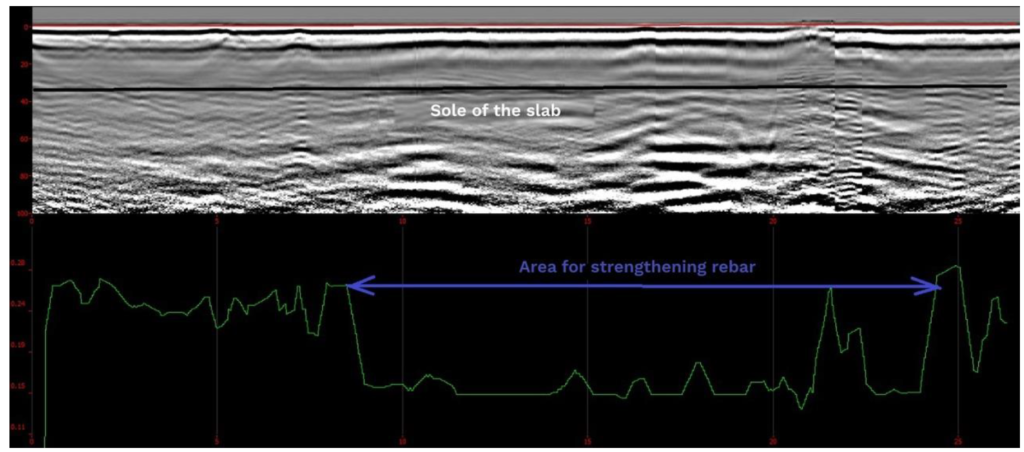

The following image is a 2D data set showing additional rebar sections in a foundation slab.

2.) Trace Conduits

Ground penetrating radar techniques help identify objects lying below the surface before coring and cutting concrete. Geotech’s Construction Scan series GPRs can identify power conduits in a reliable manner, thereby avoiding extra costs and hazards.

3.) Identify Post-Tension Cables

With ground penetrating radars, you can easily determine the depth and location of post-tension cables. Our proprietary Construction Scan solutions will help you locate PT (post-tension) cables quickly and easily.

Concrete NDT Information

1.) Locate Voids in Concrete

Construction professionals are always interested in identifying the presence of voids and cavities which may affect the structural stability of a concrete structure. GPR solutions help locate voids, cracks, and honeycombs in concrete very effectively.

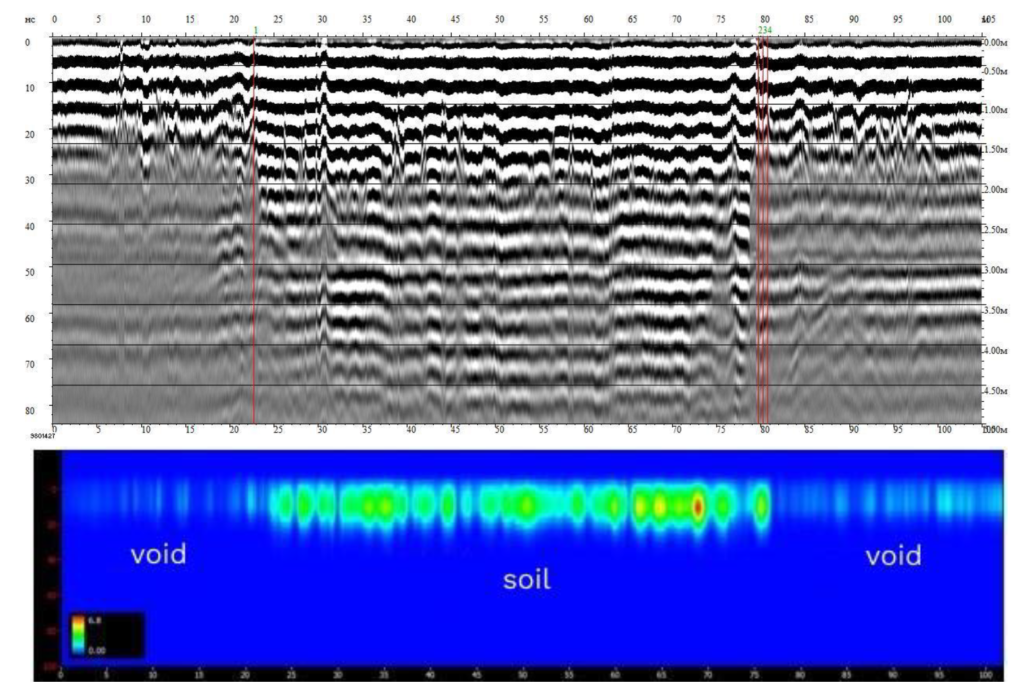

The following example demonstrates the capabilities of GPR in detecting a void behind the tunnel lining. A survey was made through an adjacent wall of parallel railway tunnels, one of which was partially filled up.

2.) Assess Concrete Condition

Concrete professionals use concrete cover data to determine if rebar (reinforcement bars) are protected from adverse environmental conditions and to locate areas which the cover fails to protect, i.e. areas of deterioration of concrete due to various factors such as fatigue, overloading, internal or external chemical attack, environmental effects, fire, or explosion.

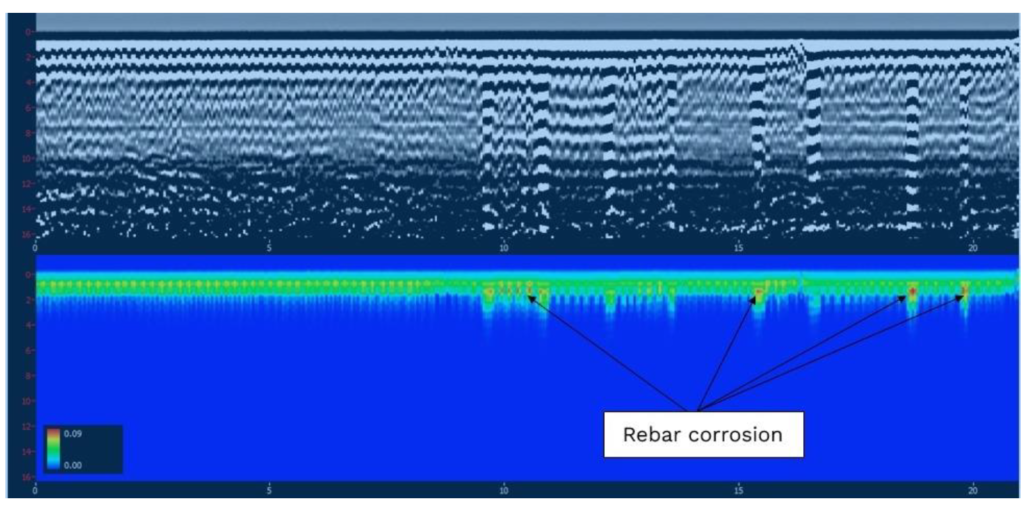

The following data illustrates clear areas of deteriorated concrete caused by rebar corrosion.

3.) Determine the Thickness of Concrete Slabs

Geotech’s Construction Scan series systems help determine the thickness of concrete slabs — of suspended or on-grade type. Advanced techniques such as antenna cross-polarizing can help improve the back-side reflections of concrete slabs.

GPR Concrete Equipment

Geotech’s proprietary Construction Scan series GPR (ground penetrating radar) is the tool designed for today’s concrete professional and made to meet all your job requirements. This heavy-duty device features a built-in display so it takes only one operator to collect, process, and interpret all data. By having this GPR in your toolbox, you can reduce risks and hazards, extra costs, and delays in work and provide a full range of services to your clients. Construction Scan is ideal for concrete inspection and NDT. Locate a variety of objects in concrete, including conduits, rebar, post-tension cables, voids and cracks and evaluate the overall condition of a concrete structure. Construction Scan can withstand the most challenging survey environments including rain, dust, and extreme temperatures from -20°C to +50°C. With our GPR systems, you can effectively detect and locate various defects in reinforced concrete such as voids, cavities, foreign inclusions, cracks, lamination; determine rebar specifications including its size, depth of occurrence, degree of corrosion; detect buried wires, cables, conduits, communications lines, and pipelines; determine the depth of a concrete structure. At Geotech Group, we provide unmatched technical support of our products and make sure our clients get the most value for the money.

-

CONSTRUCTION SCAN 1700 3D

Construction Scan 1700 3D is a portable all-in one GPR solution designed for automated localizing defects in a wide variety of wood,brick and reinforcement concrete structures, at depth of 1 m. Construction Scan 1700 includes a control processing unit, LCD...

-

CONSTRUCTION SCAN 1700

Construction Scan 1700 is a portable, lightweight and easy-to-use GPR system designed for automatic real-time location of pipes, cables, reinforcement, cracks in concrete, brick, wood and other structures at a depth of up to 1 m. Application •Detection and location...

-

CONSTRUCTION SCAN 2500

Construction Scan 2500 is a portable all-in one GPR solution designed for automated localizing defects in a wide variety of wood,brick and reinforcement concrete structures, at depth of 0,6 m. Application •Detection and location of different defects in reinforced concrete...